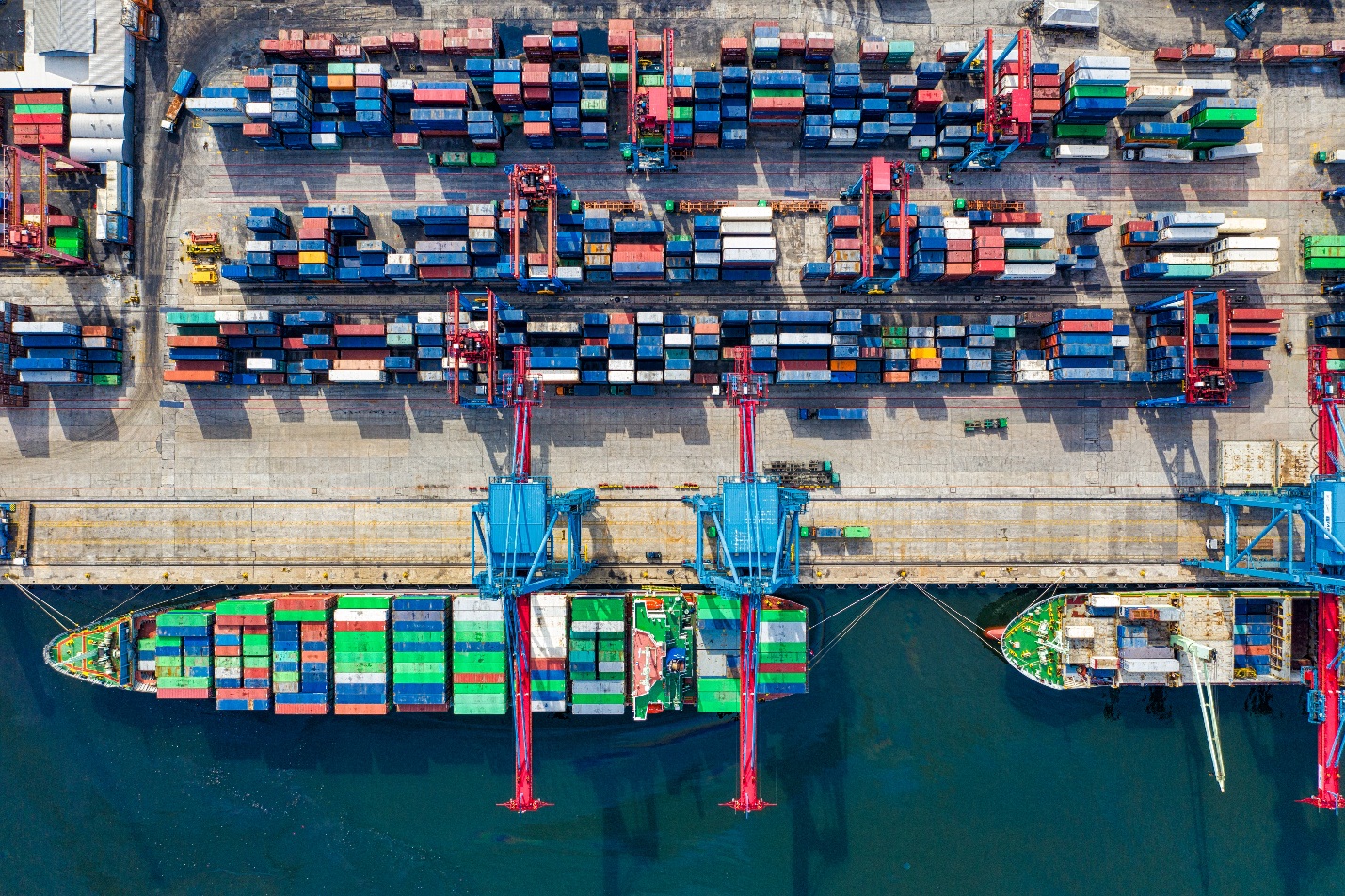

Running a business in today’s cutthroat competitive era is immensely challenging, especially given the availability of various substitute products and services. Customers can switch to another product/service in the blink of an eye if they can’t find yours in the market, whether physical or online marketplace. And that’s where your supply chain comes to play. An efficient supply chain management strategy allows you to respond to customer demands quickly and before your competitors allure them. The strategy involves working around every element of your business, from procuring raw materials, negotiating with suppliers, warehousing finished goods, and so forth. Even once the final product of your business is ready, it is the supply chain that delivers it to the end consumer. All in all, the supply chain is the soul of your business.

A single hit on your supply chain machinery can result in a devastating loss for the entire business. The recent outbreak of the Covid-19 pandemic reiterated that. Organizations worldwide faced decisive losses that wiped them out of the market only because of severe disruptions in the supply chain. According to UNCTAD, the global economy faced a loss of 4 trillion dollars due to COVID. The shocks to the worldwide supply chain were the biggest reason for such a huge loss. A few organizations that could survive those times were the ones that had robust supply chain contingency plans.

Undoubtedly, an organization’s survival is dependent on the efficiency of its supply chain management. Enhancing your supply chain processes and increasing their effectiveness will positively impact the overall business. On the contrary, slight negligence can result in irrecoverable losses. Therefore, a company needs to boost its supply chain operations to ensure survival and growth in the market. So, below we’ll discuss some effective strategies for your business to enhance supply chain efficiency.

Safeguard your assets

The supply chain is a highly capital-intensive function, compelling you to safeguard your assets in the best possible way. You must carefully consider freight insurance, necessary non-disclosure agreements, and other legal requirements to save yourself from any potential financial loss. It will have a direct impact on your operational cost. Negligence in this domain can cause serious harm to the entire business workflow.

Every other sub-element of the supply chain, including logistics, warehousing, and procurement, has many probable pitfalls. So, to gain supply chain efficiency, your safeguard mechanism should be well thought out. Otherwise, the financial hit to your supply chain in case of asset loss creates a domino effect. The impact trickles down to all business functions mainly because the supply chain is an end-to-end process. It behaves as the foundation for many other business functions. Any disturbance in it will undoubtedly disturb them as well.

Make the process easy to navigate

Supply chain processes can quickly get out of control as it involves numerous stakeholders with varying intentions and goals. Consequently, there are several operational aspects of the supply chain to cater to as well. If the entire SCM process is easy to navigate, it eventually becomes easy to control it. The best way to simplify the process is to increase supply chain visibility. The entire process should be more transparent without any information silos.

Moreover, give significant importance to stakeholder alignment so that the overall goal is parallel. Inventory management, warehousing, logistic operations, stock tracking, and other essential supply chain functions should be easy to understand. You can incorporate technology to help you control these processes. Contemporary technological solutions like Inventory Management Software (IMS) can significantly improve supply chain efficiency. Using technology, you can control functions like backorders, stock-outs, and carrying costs much more efficiently. It will provide better insights and help you perform better data analysis. As a result, the overall supply chain efficiency will significantly enhance.

Deal well with the stakeholders

The supply chain is one of those functions that extensively relies on different internal and external stakeholders. The ultimate success of the entire function depends on how well the stakeholders are aligned. You need to take extra care to set objectives and determine key performance indicators (KPIs). Once all the stakeholders are on the same page, you can generate prolific synergy that will drive operations.

From a raw material supplier to the person procuring daily office utilities, every stakeholder has a say. Specifically, if your overall supply chain orientation is based on just-in-time inventory, you radically rely on your suppliers. The repurchase schedule, inventory replenishment, and other downstream processes should be precisely timed. Your coordination with the relevant stakeholders should be top-notch. Otherwise, a single lag can disturb your entire value chain, proving financially as well as operationally devastating.

Incorporate Technology

The role of technology is significantly increasing in almost every domain of life. Specifically, the inclusion of technology in business has risen exponentially over the last decade. The contemporary business world relies heavily on technology. You cannot even imagine modern-day finance, marketing, human resource, and administrative operations to work without leveraging advanced solutions and systems. Amidst this, the supply chain function has been tremendously benefitting from technological systems, software, and other resources.

There is a massive scope of automation in the supply chain function. You can process orders through automated portals. Likewise, you can even process the order to shipping and track it in real-time through these technological marvels.

Go Green

Almost every leading logistics company is now keeping track of its carbon footprint. The modern world is now all about respecting the environment and aligning business operations accordingly. The supply chain function of every organization has a significant role to play in curbing its carbon footprint. Therefore, businesses must take adequate measures to incorporate green initiatives into their operational plans.

It will help you cut costs and take your supply chain operations towards sustainability. You can opt for eco-friendly packaging material and shipping options with a lower carbon footprint. You can also approach logistics partners who are respecting the environment and working on eco-friendly initiatives. In the long run, these green initiatives will save you a lot of costs.

Final Thoughts

The importance of the supply chain function will only increase in the business sphere. Today, businesses realize that streamlining supply chain processes can help them attain competitive advantages. However, to achieve this, they have to enhance the overall supply chain efficiency. Making the supply chain more efficient is easy but requires strategic and well-thought-out moves. So, focus on safeguarding your assets, make the process easy to navigate, deal with the partners strategically, and you’ll be well on your way to boosting efficiency.